How to Measure a Neck Finish for Continuous Thread Phenolic and Urea Closures

In the field of packaging, continuous thread closures play a pivotal role in maintaining the integrity of various products. When it comes to phenolic and urea closures, precise measurement of the neck finish is crucial to ensure seamless fit. Understand how to accurately measure neck finish empowers businesses to choose the correct closures according to their packaging needs.

Continuous thread phenolic and urea closures are known for their durability and chemical resistance, making them ideal choices for industries ranging from pharmaceuticals to food and beverages.

Phenolic caps with pulp and polyvinyl liners are perfect for general use. The liner is made of a vinyl coating applied to high density polyethylene coated paper and then it is laminated to pulpboard. This general purpose liner is commonly used for food, beverage, medical and chemical applications packed at less than 120°F., including mild acids, alkalis, solvents, alcohols, oils and aqueous products. While phenolic with pulp and foil liners are perfect for mild acids, alkalis, solvents, alcohols, oil and aqueous products.

To guarantee a perfect match, start by grasping the basics of neck finish measurement.

Why Measure the Neck Finish?

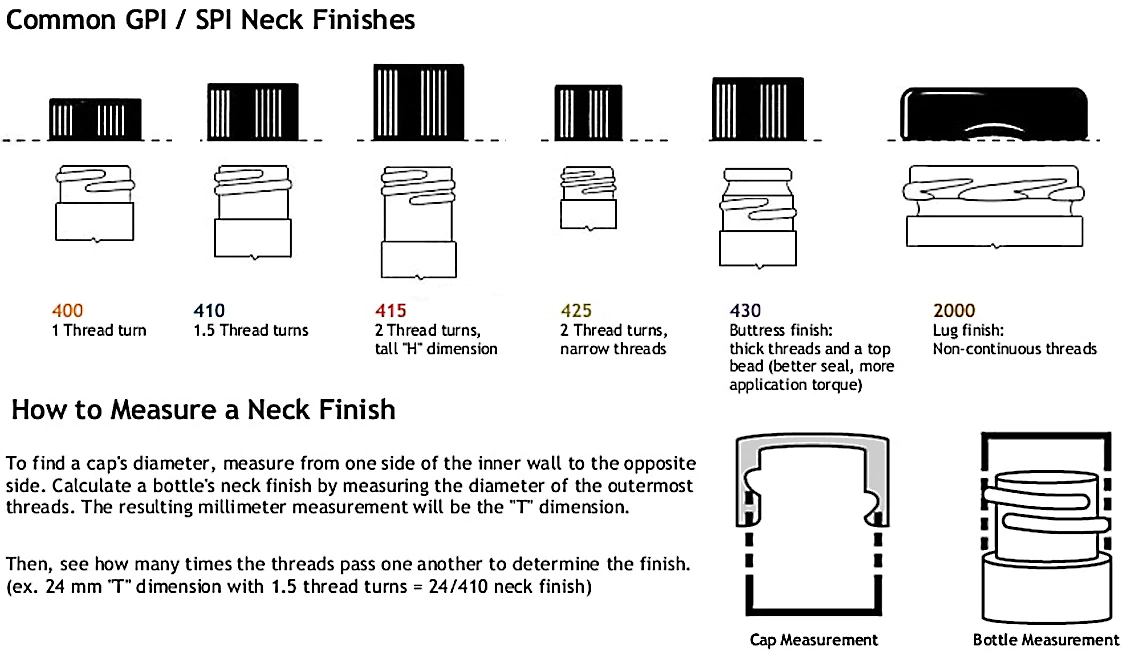

The neck finish of a bottle mouth refers to the threaded part of the bottle neck where the closure screws onto. To accurately measure the neck finish, it is important to understand the components of continuous thread closures. These closures typically consist of a closure body, liner, and thread. The closure body is the outer part that screws onto the bottle’s neck finish, while the liner provides an additional barrier, preventing product contamination. The threads ensure a secure closure and can vary in size and design.

Accurate measurement ensures safe sealing, prevents leakage and maintains the freshness of the products. In the case of phenolic and urea closures, the accuracy of the neck finish measurement directly affects the performance of the seal.

Tools Needed for Measurement

- Calipers: Using a utilize digital or manual caliper to measure the outer diameter of the bottle neck. This provides accurate measurements for selecting the appropriate closure size.

- Thread Gauge: This tool is crucialfor determining the thread pitch and angle. For continuous thread closures, understanding thread specifications can ensure a compatible pairing.

Step-by-Step Measurement Process

1.Determine the Neck Finish Type:

- Check if the neck finish is designed for continuous thread closures. This type of finish has threads on the outer side of the neck.

2.Outer Diameter Measurement& Inner Diameter Measurement:

- For closures with liners, measure the inner diameter of the neck to ensure a snug fit.

- Place the calipers around the outer circumference of the bottle neck.

- Record the measurement accurately.

3.Thread Pitch and Angle:

- Use a thread gauge to identify the pitch and angle of the threads on the bottle neck.

- This information is crucial for selecting closures with matching thread specifications.

Choosing the Right Closure

Armed with accurate neck finish measurements, the selection of continuous thread phenolic and urea closures becomes a seamless process. Consider the following factors for your specific product to ensure compatibility with your bottle or container to achieve a secure and leak-proof seal:

1.Material Compatibility: Phenolic and urea closures offer different chemical resistances. Choose a material that aligns with the contents of the bottle.

2.Liner Options: Evaluate the liner options available with closures. A appropriateliner enhances the sealing capabilities of the closure.

3.Aesthetic Appeal: In addition tofunctionality, the aesthetic aspects of the closure should also be considered. Phenolic and urea closures come in various colors and styles, complementing the overall packaging design.

Measuring the neck finish of continuous thread phenolic and urea closures is a fundamental aspect of packaging quality assurance. By investing time in accurate measurements and understanding the compatibility factors, companies can confidently choose closures that not only perfectly fit but also help improve the overall attractiveness of the product.

In the dynamic environment of packaging, the accuracy of measurement is the key to release the full potential of continuous thread phenolic and urea closures. Remember to choose closures from reputable manufacturers to ensure quality and compatibility with your packaging needs. Mastering this art can ensure that your product remains securely sealed, maintaining its freshness and integrity throughout the entire process from production to the hands of the consumer.

Italiano

Italiano Português

Português

You have observed very interesting details! ps nice internet site.Money from blog

Thank you, please continue to follow

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.